Doidge Fastenings Ltd.

Rivets, rivet setting machines and fasteners

Rivets, rivet setting machines and fasteners

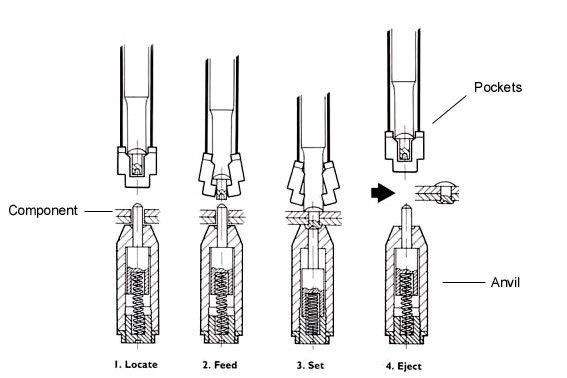

The riveting process

1. Locate

Component parts are placed either manually or automatically onto the centre pin which acts as a spring laoded location guide.

2.Feed

Rivets are continuously fed from a hopper to the riveting head, via tracks which orientate the rivet correctly.

3.Set

A high integrity static joint can be obtained by using the maximum shank expansion in the component of a semi tubular rivet. Precision swivel joints can also be achieved by using punched tubular rivets and minimizing shank expansion.

4. Eject

Workpiece is removed either manually or automatically, before the process returns to step 1.

Component parts are placed either manually or automatically onto the centre pin which acts as a spring laoded location guide.

2.Feed

Rivets are continuously fed from a hopper to the riveting head, via tracks which orientate the rivet correctly.

3.Set

A high integrity static joint can be obtained by using the maximum shank expansion in the component of a semi tubular rivet. Precision swivel joints can also be achieved by using punched tubular rivets and minimizing shank expansion.

4. Eject

Workpiece is removed either manually or automatically, before the process returns to step 1.