Rivets, rivet setting machines and fasteners

The bottom track is arguably the most simply, yet important factor in achieving a consistent supply of rivets to the pockets and thereby efficient production.

Particular attention should be paid to the following points: -

1. The tracks must be kept free from dirt and foreign matter: accordingly they must never be oiled or greased, and should only ever be wiped with a clean, non-fluffy cloth

2. Hard objects, such as screwdrivers or metal spikes, must never be used on the tracks (especially to un-jam them).

Fitting of new ‘Bottom Track’

Ensure the machine is not running and switch power off at the isolation box. Unfasten the two screws and remove old bottom track.

Fit the new bottom track into position. Trip machine and turn flywheel by hand, very carefully, until the plunger just touches the back of the track sufficient to lightly mark the surface. (If necessary, lightly tap the bottom of the track with a soft hammer.

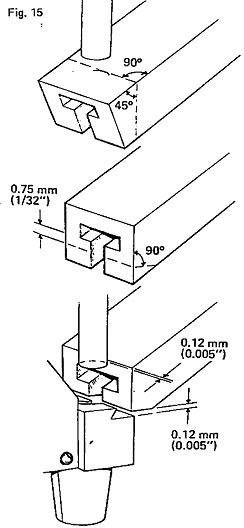

Remove the track and mark a line square with the edges, in line with the uppermost part of the mark made by the plunger.

On the side of the track, draw a line at an angle of 45° in a direction towards the track exit. Remove the excess metal up to that mark. Refit track and check that there is a 0.12mm (0.005”) gap between the plunger and the bottom of the track. Machine or file this face until the correct gap is achieved. Cut bottom of the track at 90° to the first cut to give a length on the stem of the ‘T’ of 0.75mm (1/32”). For rivets with a head diameter of 3mm (1/8”) or less, this dimension could be reduced to 0.25mm (0.010”).

Deburr and clean out the ‘T’ slot, and refit the bottom track to the machine. Refit pockets. The machine is now ready for operation.

As a final precaution, check the machine cycle by hand to ensure it cycles without a problem.